Con-Tech supplies Intermediate Bulk Container (IBC) parts and fittings produced by global sourcing suppliers, many of whom are ISO certified, in China, Taiwan, India and elsewhere. Our industrial packaging suppliers offer the best of advanced technology for IBC parts and fittings with production under strict quality control.

The IBC is a Flexible Form of Packaging

The IBC, a reusable, flexible or rigid cross between a drum and industrial bulk transport which can be moved by forklifts or pallet trucks, has become more and more common. The concept of the IBC was first patented in the 1990s. Cube-shaped, the IBC became more popular as it was easily stored and shipped, and used space more efficiently than other containers. Additionally, the IBC’s durability and easy handling make it a preferred form of global packaging.

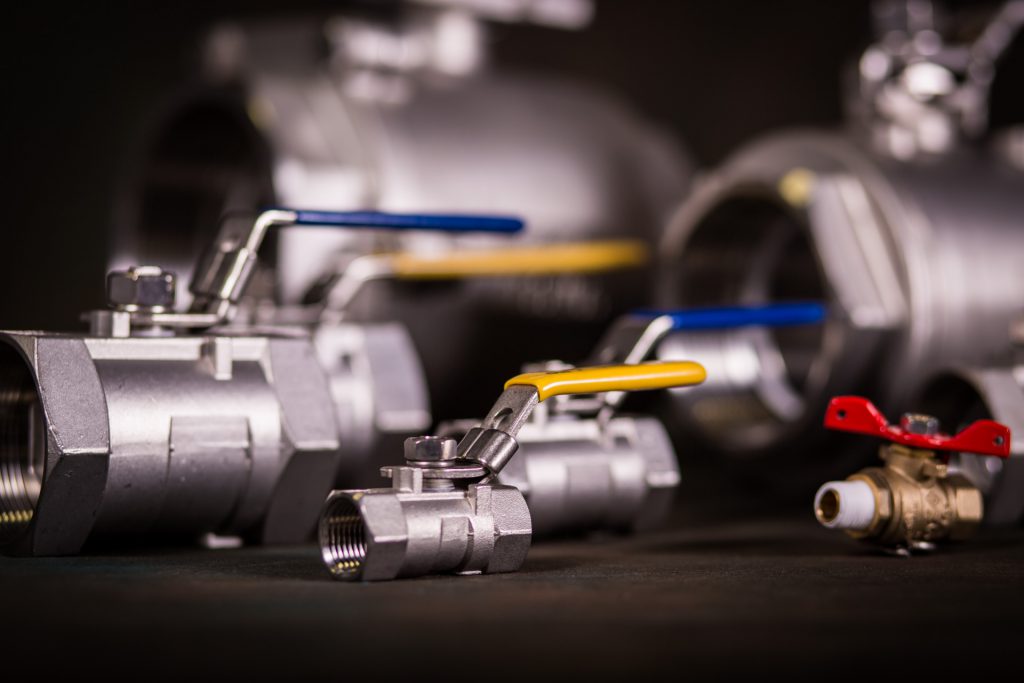

The stackable rigid IBC comes in many sizes from the frequently used 275 and 330 US gallon IBC up to 793-gallon IBC. The rigid IBC is made of metal, plastic or a composite and most have a built-in valve through which the contents can be poured. The flexible IBC also can be made of fiberboard, wood, aluminum, and folding plastic. Composite IBCs use plastic liners that are versatile and economical.

Uses of an Intermediate Bulk Container

The intermediate bulk container market is poised to grow by $ 3.18 bn during 2021-2025, with containerization a big market driver. Growth in manaufacturing and construction is another large contributors to the IBC trend. Con-Tech is pleased to serve this ever growing IBC market. Growth in manufacturing is another large contributor to the IBC trend. Serious consideration needs to be given to the transit and storage of IBCs and there are complex rules governing these issues. But all agree that there are many benefits to IBC use. And the innovations in the IBC world keep coming.

IBCs may be purchased or leased. They typically contain a vast array of items from paints, chemicals, and petrochemicals to food, pharmaceuticals, healthcare products, and commodities. Con-Tech continues to provide IBC parts & fittings to all of these industries.

Using the correct drum and IBC closures and accessories is critical as the area is strictly regulated. Organizations of manufacturers of reconditioned and new steel, plastic and fiber drums as well as intermediate bulk containers work hard on their members’ compliance. Manufacturers of new industrial packaging and their North American suppliers do the same while emphasizing the importance of safety and reliability.

Don’t see what you are looking for? Need a part made? Click the RFQ button, email info@con-techinternational.com or call us at 1-504-523-4785 for IBC and custom products.