Con-Tech’s procurement outsourcing includes handling all of your metal stamping and custom manufacturing needs through our suppliers in China, Taiwan, India and elsewhere, many of whom are ISO certified. They provide cost-effective manufacturing processes whereby metal sheets are fed into a press that converts them into high quality, durable shapes. Basic techniques of progressive, four slide or deep draw metal stamping are used, while CAD/CAM engineering technology produces optimal results through procedures like blanking, bending, coining, embossing, flanging, piercing, and punching.

Our metal stamping uses custom tooling and techniques to meet our customer’s high-volume production needs and ensure all parts meet their exact specifications. Our metal stamping partners use materials that are tested to and meet all relevant industry standards of our procurement outsourcing customers. All metal stamping parts are inspected to ensure dimensional accuracy and adherence to your expectations. We strive to put an unlimited range of cost-effective metal stamping and custom manufacturing capabilities at your disposal.

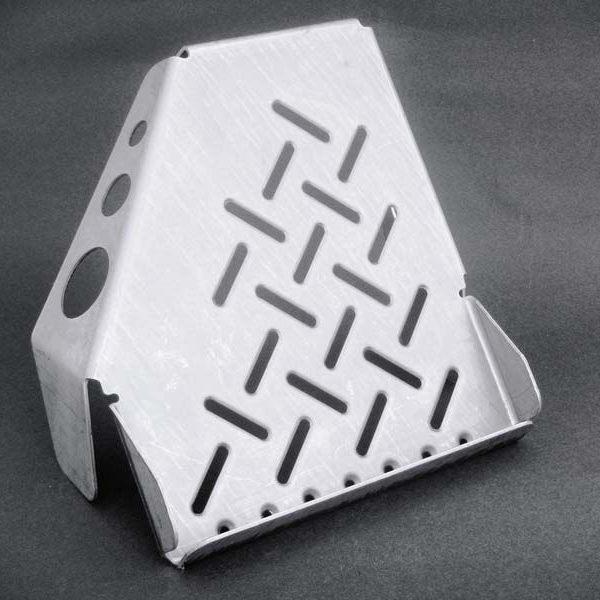

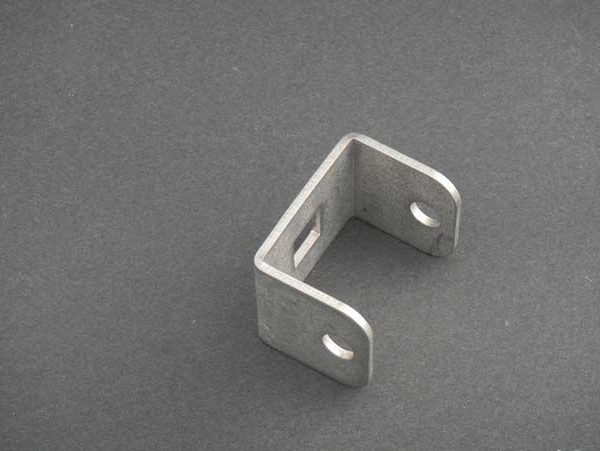

Metal Stamping Custom Manufactured Part Examples

3mm Carbon Steel Footing 2.3mm Carbon Steel Tread : Left 2.3mm Carbon Steel Tread, Right 304L Crossover Anchor Bracket, Stainless Steel 12 GA. Brake Shoe, Hot Rolled Steel Bracket, Auger Housing Bracket, Auger Housing Pipe Joint Bracket, Welded Stud Bracket, Welded Stud

For more information about our products and services, click the RFQ button, email us at info@con-techinternational.com or call us 1-504-523-4785.