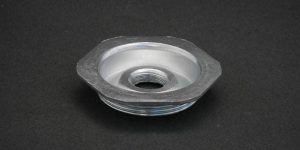

IBC & Tote Tank Closures and Accessories

Con-Tech supplies IBC & tote tank closures produced by global sourcing suppliers, many of whom are ISO certified, in China, Taiwan, India and elsewhere. Our industrial packaging suppliers offer the best of advanced technology for IBC parts and fittings with production under strict quality control.

The stackable rigid IBC comes in many sizes from the frequently used 275 and 330 US gallon IBC up to 793-gallon IBC. The rigid IBC is made of metal, plastic or a composite and most have a built-in valve through which the contents can be poured. The flexible IBC also can be made of fiberboard, wood, aluminum, and folding plastic. Composite IBCs use plastic liners that are versatile and economical.

The intermediate bulk container market is poised to grow by $ 3.18 bn during 2021-2025, with containerization a big market driver. Growth in manufacturing and construction is another large contributors to the IBC trend.

Showing 17–24 of 61 results

Frequently Asked Questions About IBCs, Tote Tanks and Closures

What is a Tote Tank or IBC?

A tote tank or intermediate bulk container is a cube-shaped, stackable, rigid or flexible cross between a drum and industrial bulk transport. It comes in many sizes from the frequently used 275 and 330 US gallon IBC up to 793-gallon IBC. The rigid IBC is made of metal, plastic or a composite and most have a built-in valve through which the contents can be poured. The flexible IBC also can be made of fiberboard, wood, aluminum, and folding plastic. Composite IBCs use plastic liners that are versatile and economical. Tote tanks have become common since first patented in the 1990s.

What are the Benefits of an IBC?

The IBC is popular as it is reusable, durable, easily handled, stored and shipped, and uses space more efficiently than other containers. It also has an advantage in that it may be either purchased or leased.

What is Shipped in a Tote Tank?

A vast array of items from building supplies, paints, chemicals, and petrochemicals to food and beverage, pharmaceuticals, healthcare products, and commodities are shipped in tote tanks. According to one research study, the IBC market is set to cross a US $10 billion market soon as the packaging industry shifts away from plastics and plastic-based composites, with 80% of the IBC market being the food and beverage, industrial chemical, and building and construction industries.

Of What is an IBC Composed?

The rigid IBC is made of metal, plastic or a composite and most have a built-in valve through which the contents can be poured. The flexible IBC also can be made of fiberboard, wood, aluminum, and folding plastic. Composite IBCs use plastic liners that are versatile and economical.

Why Vent an IBC?

The IBC vent prevents excessive internal pressure in the IBC. When the IBC’s internal pressure reaches a certain level the vent adjusts the internal pressure to ensure safe handling. If an IBC valve is opened without venting, a vacuum can be created causing the IBC to collapse. Conversely, if an IBC is filled without venting it can explode.

What is the Role of Venting in Vacuum Deformation of an IBC?

If the inner receptacle of an IBC is not vented, vacuum deformation of an IBC can be caused.

What is the Role of an IBC Vent when Outside Temperature Increases?

When the temperature outside an IBC increases the IBC vent needs to be released in order to avoid an explosion.

What is the Role of an IBC Vent when Outside Temperature Decreases?

When the temperature outside the IBC decreases and the IBC is not properly vented, suction can be created deforming the IBC, creating suction and making it difficult to remove the lid.

Why is an IBC Gasket Important?

Using the right IBC gasket prevents leaks and helps keep the product clean and sanitary.

How Can Con-Tech Help You?

Con-Tech can supply all of your just in time delivery requirements. Click the RFQ button, email info@con-techinternational.com or call us at 1-504-523-4785 for more information. Tell us what you need and we will save you time and money.