Marine Hardware

Con-Tech conveys the specifications for your wholesale custom manufactured boat parts and marine hardware to the right manufacturer for your unique application. Con-Tech will stay with you every step of the way from design, prototype, production import, and delivery to ensure that there are no unwanted surprises in your wholesale custom manufactured boat part or marine hardware experience.

What makes Con-Tech different from other wholesale custom manufactured boat parts and marine hardware manufacturers is our attention to detail and our knowledge of your industry. We are tenacious and thrifty and we use our expertise to stay with you every step of the process. And, Con-Tech works exclusively with world-class, wholesale custom manufacturers, many of whom are ISO certified, to get you the product you need.

Covid 19 increased marine hardware sales and the post-pandemic effects have been equally strong. According to the National Marine Manufacturers Association, sales of all marine products and services including boats rose to 13-year high in 2020 to $47 billion, increasing 9% from the prior year. The boating industry has touted data showing that new powerboat sales are strong, along with sales of pontoon boats, wake sport boats, and jet boats.

The trend has shown enormous potential for the future as first-time buyers are entering the market in record numbers increasing wait times and straining dealer inventories. The EU and U.S. reached an interim agreement in 2021 that prevents the doubling of tariffs on U.S. boats and engines – which also offered encouraging news for marine manufacturers.

Con-Tech is proud to serve the growing needs of the marine manufacturing industry.

Showing 9–16 of 34 results

Frequently Asked Questions About Marine Hardware

Why use stainless steel in marine hardware?

High-grade stainless is preferred in many marine hardware applications as it may last more than 1000 years. Stainless Steel is an iron-containing metal alloy made up of two or more chemical elements. It comes in more than 57 stainless steel alloys along with numerous proprietary alloys.

What are the benefits of stainless steel in marine hardware?

Stainless steel is used in marine and shipbuilding as it is highly resistant to rust and less likely less to corrode in saline conditions.

Why use brass in marine hardware?

Brass is valued in marine hardware as is malleable and ductile.

What are the benefits of brass in marine hardware?

Brass is easy to form into desired shapes and forms while retaining high strength. It is a metal alloy of copper and zinc that is prized for many valuable properties which vary depending on the copper-zinc ratio.

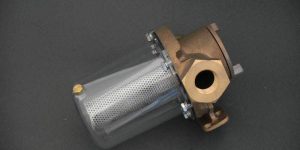

Why use bronze in marine hardware?

Bronze is highly resistant to seawater corrosion.

What are the benefits of using bronze in marine hardware?

Bronze is a tin alloy that has superior resistance to ammonia stress corrosion cracking compared with brass. On the whole, the higher the tin content, the higher the seawater corrosion resistance. When properly manufactured, bronze tends to corrode evenly and has little tendency to pit. Thus, bronze is used for marine hardware like cockpit drain scuppers, as well as propellers, submerged bearings, springs, bearings, gears, and fasteners.

How Can Con-Tech Help You?

Con-Tech can supply all of your just in time delivery requirements. Click the RFQ button, email info@con-techinternational.com or call us at 1-504-523-4785 for more information. Tell us what you need and we will save you time and money.