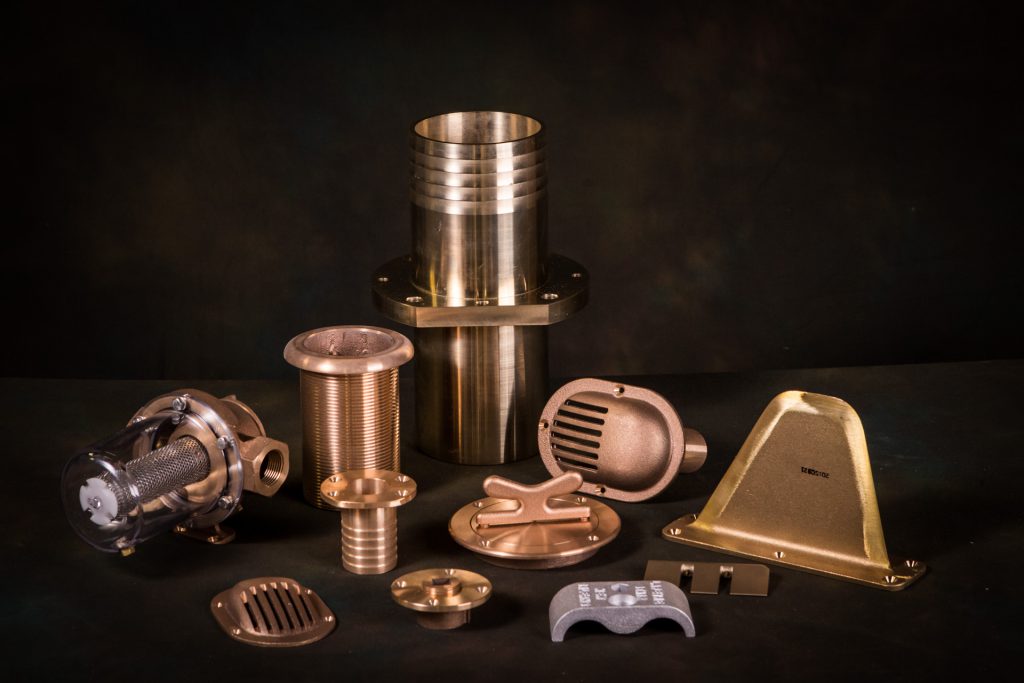

Con-Tech is a global parts supplier of standard and custom parts of carbon steel, stainless steel, and plastic for industrial packaging such as drums, IBC’s, tote tanks, plastic containers, and diverse products for the petrochemical, marine, automotive and other industries. You provide your product needs; target price and timetable and we match your needs with the right source.

Where you seek a custom manufactured product, we use our vast global parts supplier network, many of whom are ISO certified, to quickly provide a proposal. From concept through design, prototyping, production, import and delivery, Con-Tech sources the best manufacturing expertise in casting, machining, stamping, fabricating and assembly.

We know the best in global parts procurement and offer suggestions and alternatives to save you money. Throughout the process, Con-Tech streamlines your purchase and delivery experience with consistent and reliable service.

Benefits of Having a Global Parts Supplier

Having a global parts supplier for outsource manufacturing is a logical alternative for companies that wish to avoid the time, costs, and problems of manufacturing themselves. Con-Tech handles all of your global parts supplier requirements so you do not have to divert limited resources away from your core product. And this eliminates the need for you to navigate the language barriers, cultural differences, fluctuating exchange rates and trade restrictions that can be so frustrating.

May of our world-class, ISO-certified suppliers in China, Taiwan, India and elsewhere are experienced in casting, stamping, deep drawing, CNC machining, fabricating, finishes, forging, plating, anodizing, polishing, and injection molding. Con-Tech’s global parts suppliers for outsource manufacturing handle your specifications with materials that are tested to meet all relevant standards for your industry. This allows Con-Tech’s global parts supplier partners to consistently deliver a wide range of parts that are produced to meet challenging requirements. Each job is crafted with pride and care that shines through in the finished part.

Living in a post-COVID world has forced companies to examine their supply chains and evaluate the ongoing risks and challenges posed by global shifts. Acknowledging these worldwide shifts has emphasized the importance of global sourcing.

Global parts sourcing is critical in a world where it is very difficult for one company to possess the more sophisticated skills, technology and materials needed. Especially where requirements like precision castings are needed, reliance on powerhouse foreign producers is becoming essential. Even though thoughts of distant parts suppliers can be daunting, the positive benefits of a global supply chain are well established.

Why Using Con-Tech Works

What makes Con-Tech different than other global parts suppliers is our attention to detail and our knowledge of your industry. We are tenacious and thrifty and we use our expertise to stay with you every step of the process from design, prototype, production, and import to delivery.

As a key global parts supplier for outsource manufacturing for more than 35 years, Con-Tech’s strong relationships with global suppliers and manufacturers and our logistics expertise allow us to master the recent changes in American tariff regulations and related issues with ease. Customer satisfaction is our top priority.

Call 504-523-4785, click on the RFQ button or email us at info@con-techinternational.com to learn more about having a true professional parts manufacturer make, assemble, and deliver items designed especially for you.